Components, Functions & Applications

What is an HMI?

HMIs are user interfaces that enable interaction with machines. They are widely used in industrial settings, primarily for control and monitoring purposes.

Definition

What is an HMI?

HMI is short for for Human-Machine Interface, a user interface that allows a person to interact with a machine via buttons, switches, touchscreen displays or other means.

We encounter HMIs in everyday life – from ATMs and elevators to vehicle systems and household appliances.

In industrial environments, HMIs play a crucial role. As a key part of the automation infrastructure, they are used to control and monitor a wide range of systems, including CNC machines, injection molding machines, and PLC-controlled production lines.

In the following sections, we will explain how a typical HMI is structured, what functions it performs, and where HMIs are used in industrial settings. Additionally, we will explore recent advancements in HMI technology.

Components

How is an HMI structured?

A typical industrial HMI consists of various hardware and software components that facilitate input, output, and communication with connected systems.

Key components of a traditional HMI:

- Display: Visualizes data, processes, and control options (e.g., LED/LCD display, touchscreen).

- Input devices: Enable user interaction with the system (e.g., mouse, keyboard, touchscreen).

- Hardware interfaces: Facilitate connections to external devices and systems (e.g., USB ports, Ethernet ports, serial interfaces like RS232 and RS485).

In the case of a touchscreen, input and output are combined into a single component.

The graphical capabilities of an HMI can vary significantly, ranging from simple symbols and numerical values to fully customizable dashboards with various visualization types.

The interfaces required for an HMI depend heavily on the specific machine and its lower-level control systems. Additionally, communication interfaces and protocols for integrating with higher-level software systems must be considered. One widely used standard for vendor- and platform-independent data exchange between devices and software applications is OPC UA.

A traditional HMI is often part of a SCADA system (Supervisory Control and Data Acquisition). While the HMI provides a direct, typically local interface for operating a machine, a SCADA system manages multiple HMIs and enables centralized process monitoring.

Functions

Functions of an HMI

HMIs are a core component of many industrial environments. In the traditional automation pyramid, they are positioned at the process control level, serving as the primary interaction point for operating machinery and systems. Unlike applications at the operations management level (e.g., MES) or enterprise level (e.g., ERP), HMIs are typically located directly near the machine.

The core functions of a traditional HMI include visualizing data for control, diagnostics, and monitoring, as well as controlling machines and processes. Additionally, HMIs can record data or trigger alarms when necessary.

Data visualization

Depending on the type of machine, process and operational data can be displayed in various formats.

Examples:

- Gauge charts / tachometer displays for rotational speed, pressure, and temperature values

- Bar / column charts for energy consumption

- Line charts for temperature fluctuations

- Traffic light systems for operating statuses

- 3D models for interactive visualization of individual components

Example for the visualization of production data with manubes

Control

The options to interact with a machine and operate it through an HMI can also vary quite alot, especially depending on whether the HMI comes in the form of an interface directly attached to machine, a computer or a mobile device.

An HMI may use buttons and switches, mouse and keyboard, or touchscreens. The latter are common in modern HMIs.

Monitoring, diagnosis and alarms

The visualization of data through an HMI is not only intended to support machine control but also plays a crucial role in real-time process monitoring (see also production monitoring).

Ideally, a HMI helps detect errors and deviations immediately, utilizing appropriate visuals and allowing for quick responses.

Additionally, HMIs can trigger warnings and alarm messages – for example, when a specific threshold falls below a critical value.

Data recording

Process data collected by an HMI can be stored and used for later analysis, for example, when reviewing historical data in the context of production optimization.

Areas of application

Industrial use of HMIs

HMIs play a crucial role in industrial production but are also used in building automation, logistics, medical devices, and many other fields.

In the manufacturing and process industries, HMIs enable the operation and monitoring of production lines, machines, and robots. Modern HMIs can visualize key process data and production metrics in the form of dashboards, increasing transparency throughout the organization. This, in turn, can lead to reduced downtime and more efficient processes.

In building automation, HMIs are used to control heating, ventilation, and air conditioning systems (HVAC).

Advancements

Evolution of HMI systems

The term HMI (Human-Machine Interface) is broadly defined and can – depending on the interpretation – encompass a wide range of systems for controlling and monitoring machines.

While traditional HMIs were often installed locally on the machine, a dedicated computer, or a touch panel, modern technology allows HMIs to be used in a distributed environment, where users can access the system from different locations.

Web- and cloud-based HMIs take this concept even further, enabling users to remotely access machine interfaces via a web browser without needing to install special software. This requires a secure network connection to the relevant machines (for an example of how this can be implemented, see our page on system integration with manubes).

Compared to traditional HMIs, cloud-based HMIs offer several advantages.

Advantages of web-based HMIs

Centralized Management

Updates, configurations, and maintenance can be performed remotely and more efficiently.

Mobile Access

Users can access an HMI remotely, often from any location and on mobile devices.

Cost Efficiency

By eliminating the need for local infrastructure, maintenance and hardware costs can be significantly reduced.

Cost Efficiency

Depending on the architecture and supported interfaces, additional machines can be easily integrated.

Centralized Management

Updates, configurations, and maintenance can be performed remotely and more efficiently.

Mobile Access

Users can access an HMI remotely, often from any location and on mobile devices.

Cost Efficiency

By eliminating the need for local infrastructure, maintenance and hardware costs can be significantly reduced.

Cost Efficiency

Depending on the architecture and supported interfaces, additional machines can be easily integrated.

Cloud-based HMIs offer another key advantage: Their proximity to the enterprise level makes it easier to integrate them with AI, Big Data, and similar applications, enabling the use of collected data for process optimization.

Additionally, cloud platforms that serve as HMI solutions can implement their own data processing functions.

An example is our manubes platform which offers advanced features such as the Datamodel Designer, Workflow Designer, and AI-powered Chat Assistant to enhance industrial data and process management.

Common interfaces for cloud communication include MQTT and REST, both supported by manubes.

manubes

manubes as an HMI solution for manufacturers

Our cloud platform manubes enables real-time visualization of machine data and provides interactive controls for direct access to automation systems and processes.

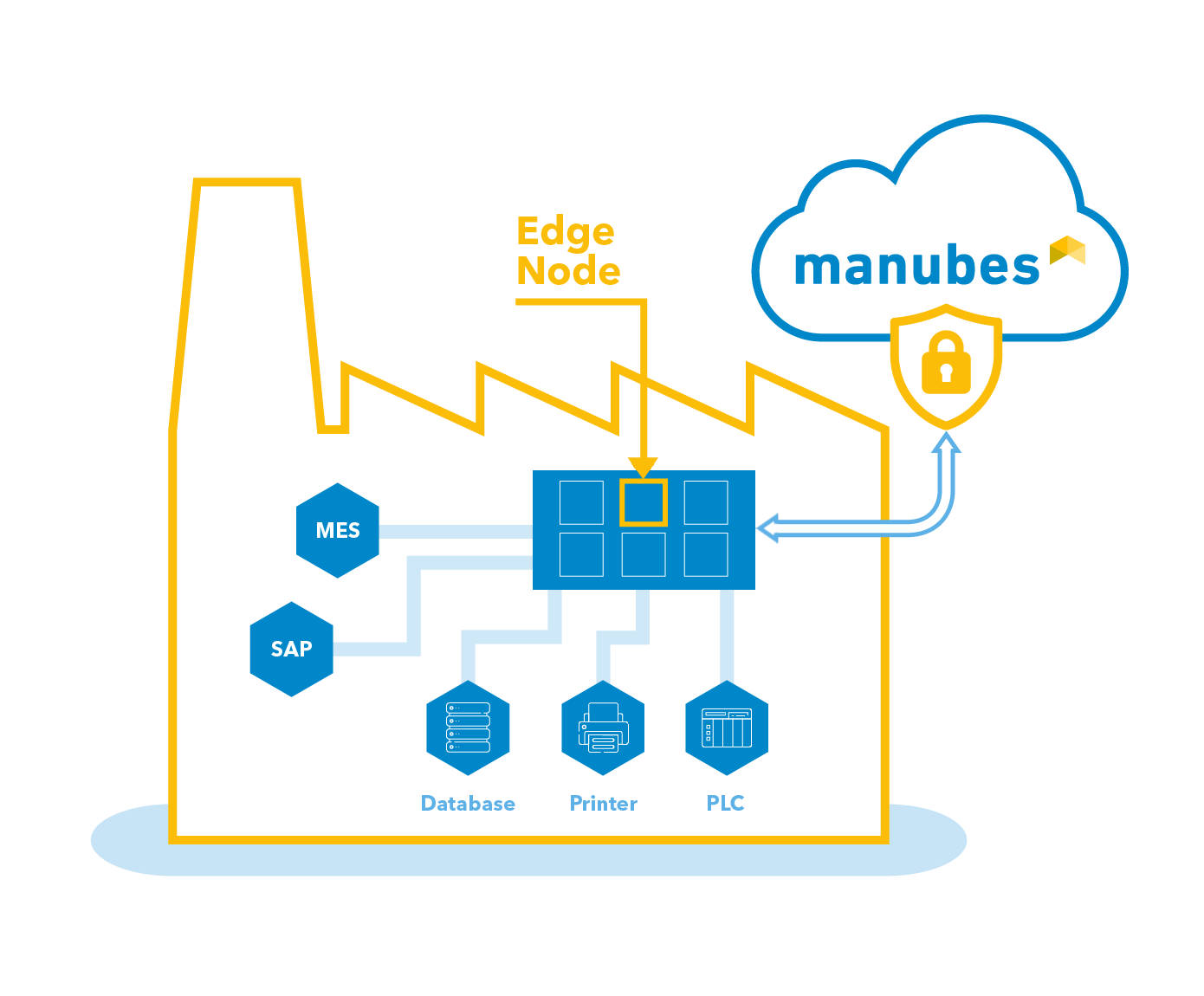

To ensure secure connections to distributed facilities, manubes leverages the concept of edge computing. Edge Nodes operating within local networks process production data and establish secure, bidirectional connections between local systems and the manubes cloud.

manubes delivers all the previously mentioned benefits of a cloud-based HMI. Companies can access all platform functions remotely, eliminate the need for on-premise server hardware, and benefit from high flexibility and scalability.

Additionally, manubes offers a wide range of intuitive tools for managing industrial data and processes. With no-code design tools, production teams can develop custom solutions without requiring extensive programming expertise.

Cloud connection of local production systems with manubes

Conclusion

HMIs remain essential while becoming more versatile

HMIs are essential interfaces for machine control and monitoring and will continue to play that role in the future. Yet, traditional HMIs as described in the automation pyramid have increasingly been complemented by new concepts driven by digitalization.

One significant factor in this evolution is the widespread adoption of standardized, internet-based interfaces such as OPC UA, which has enabled seamless machine communication via centralized systems.

Discover manubes!

Cloud-based production management with manubes: Our innovative platform offers specialized tools for connecting production systems, managing and visualizing production data and automating production processes. manubes users benefit from a powerful infrastructure, worldwide access and maximum security.