Explanation & Examples

What is a SCADA System?

A SCADA system is a computer-based architecture that enables the monitoring and control of industrial facilities and processes.

Definition

What is SCADA?

SCADA is short for for “Supervisory Control and Data Acquisition” and refers to a system architecture used for monitoring, controlling, and collecting data in industrial processes.

Typically decentralized, SCADA systems consist of a central control unit, known as the SCADA server, and multiple distributed Human Machine Interfaces (HMIs).

A SCADA system communicates with programmable logic controllers and remote terminal units to capture selected data points, trigger alarms if necessary, and provide set values for automated process control.

Differentiation

Differences between SCADA and HMI

The terms SCADA and HMI are frequently used together, with HMIs serving as essential components within more complex SCADA systems.

- HMIs, or Human Machine Interfaces, serve as the direct user interfaces that allow for visual control of machines and processes.

- SCADA refers to a comprehensive system that collects, stores, and analyzes data from various machines and sensors. It can integrate multiple HMIs, facilitating extensive process management.

Features

Features of a SCADA system

Complete SCADA systems comprise several components including sensors, controllers such as PLCs, communication networks, and central software for data processing.

Their primary functions include:

-

- Real-time collection of machine and process data

- Remote control of machinery and processes

- Graphical representation of operational data in dashboards

- Alert management for notifications on faults or disturbances enabling rapid response

- Reporting and analysis through the storage of historical data to optimize operations.

Industrial Use

Where are SCADA systems used?

SCADA systems are utilised across a variety of sectors.

Energy: Managing and monitoring electricity grids and water treatment facilities

Transport: Managing traffic systems and rail operations and the oil and gas industry for monitoring pipelines and refineries.

Building automation: Automation and control of HVAC systems

Industrial manufacturing: Overseeing production lines and processes

New Developments

Cloud-based SCADA systems

Traditionally, SCADA systems were local and more or less isolated from each other.

However, modern advancements are increasingly moving SCADA to the cloud, unlocking new opportunities:

-

- Users can access SCADA data globally through web interfaces.

- By leveraging local edge components or gateways, data can be processed on-site and efficiently transported to the cloud.

- Companies can manage collected data centrally for advanced analysis using artificial intelligence and big data techniques.

- Businesses can take advantage of scalable cloud resources, enabling quicker and more cost-effective integration of new facilities or locations.

manubes

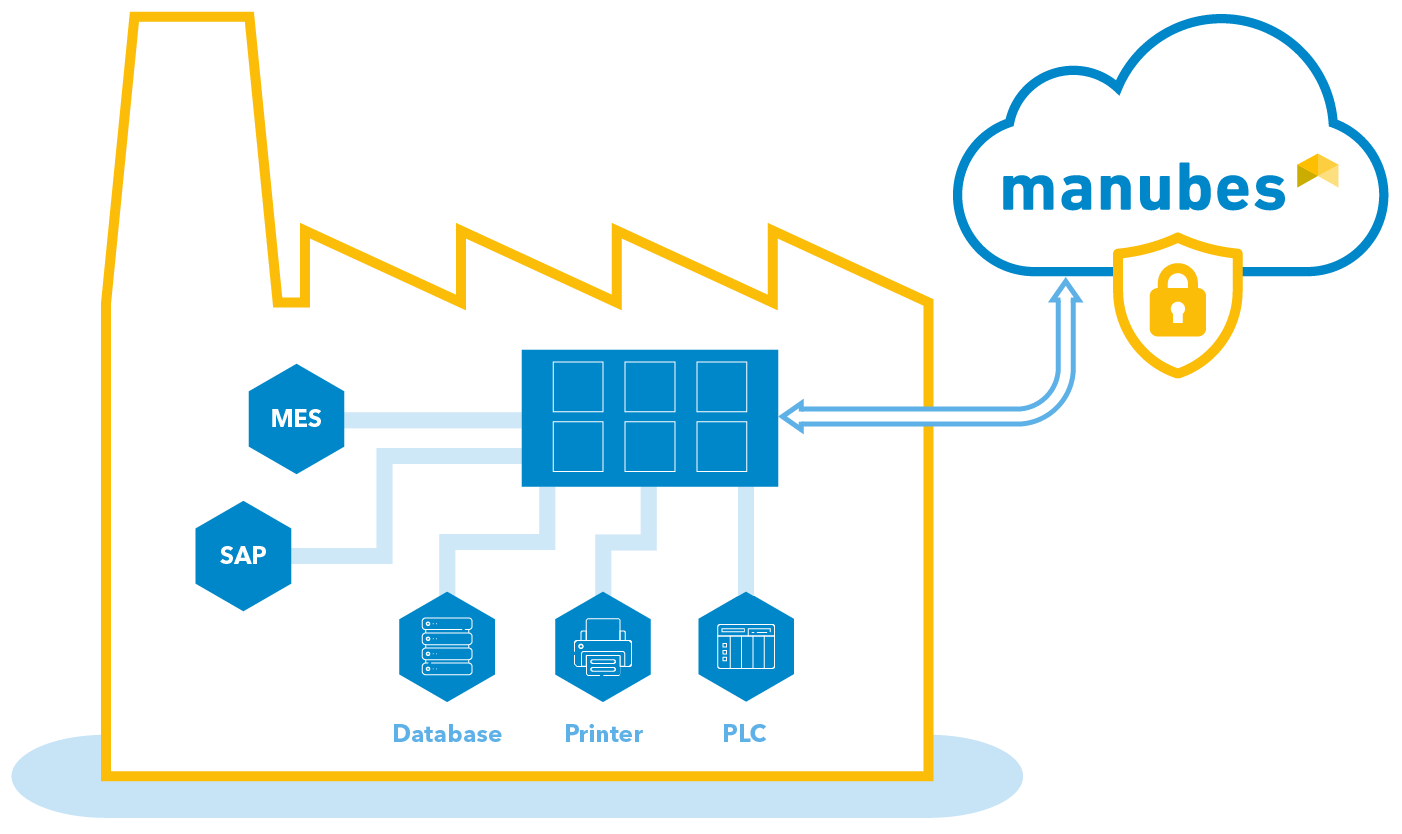

manubes as part of a SCADA system

With manubes, companies can capture, visualize and process data from distributed plants and systems within a unified cloud environment, enabling advanced analysis and automation.

Through local Edge Nodes and standard interfaces like OPC UA, manubes users can directly access automation devices and processes.

manubes not only integrates the core functions of modern SCADA systems but also offers all the advantages of a cloud-based infrastructure, including reduced hardware and licensing costs, mobile accessibility, scalable resources, and collaborative working.

The platform enables real-time visualization of process data through customizable production dashboards that are accessible on any device. Additionally, the AI-powered Chat Assistant provides insights into existing data within seconds, aiding companies in both daily monitoring and long-term optimizations.

With support for common industrial and database interfaces, manubes facilitates targeted connections to existing production systems. As a flexible cloud platform, manubes can complement existing SCADA systems or serve as a lightweight and scalable cloud-SCADA solution.

Cloud integration of local production systems with manubes

Conclusion

Technological innovations lead to new opportunities in SCADA

SCADA systems play a crucial role in many industries, fulfilling essential functions in areas like production monitoring and production control. Yet, the specific structure of a SCADA system is not set in stone and typically adapts to existing environments and requirements.

The advancement towards cloud-based systems and AI-enhanced analytics presents new opportunities, enabling companies to process larger volumes of data and scale more rapidly while simplifying data access.

With our cloud platform manubes, manufacturers can expand the functionality of their existing SCADA system or build an innovative cloud-based SCADA system.

Cloud-based production management with manubes

manubes is a cloud platform specifically tailored to the needs of manufacturers. With manubes, companies of any size are able to rapidly develop future-proof solutions in areas such as production planning, process control and asset monitoring.