Ongoing digital transformation in manufacturing requires powerful interfaces and protocols in order to network machines, sensors and other systems efficiently, securely and scalably.

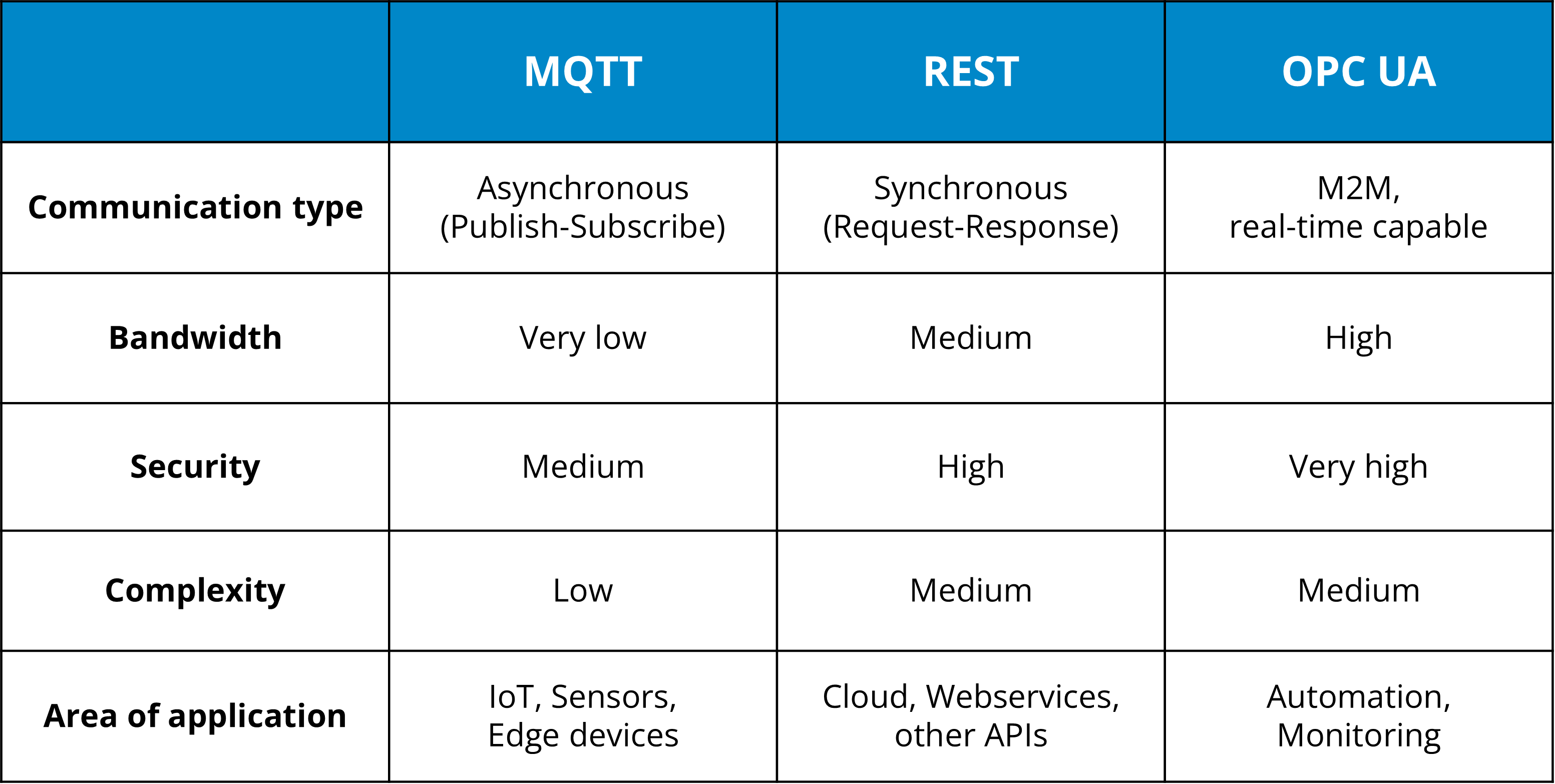

Three of the most commonly used communication standards are MQTT, REST and OPC UA. But which technology is suitable for which application?

In this article, we look at MQTT, REST and OPC UA, comparing their main characteristics and using practical examples to show when which standard is the right choice.

What are MQTT, REST and OPC UA?

MQTT, REST and OPC UA are technologies that enable the exchange of data between various devices and software systems.

Yet there are key differences between them, regarding e.g. the layer of communication and the most common areas of application.

MQTT

MQTT is a lightweight network protocol for IoT communication that even smaller devices can use to send and receive messages.

MQTT is based on a publish-subscribe model: Devices and applications (MQTT clients) publish data on so-called “topics” to a central broker. Other clients can subscribe to selected topic structures in order to receive the associated messages via the broker.

Main characteristics of MQTT:

- Asynchronous communication

- Low bandwidth and device resource requirements

- QoS levels for reliable message transmission

Typical MQTT applications include IoT devices and platforms, sensor networks and predictive maintenance.

REST

REST is an architectural style for web-based interfaces based on HTTP requests.

A server provides selected resources via a web interface, the REST API. Client applications address a resource using a unique address and use HTTP methods such as GET, POST, PUT or DELETE to retrieve, create, change or delete data.

Main characteristics of REST:

- Client-server model

- Statelessness (API requests are self-contained and independent of each other)

- Scalability through multi-layer architectures (client only knows the interface, technological implementation remains hidden)

REST is based on common Internet technology, which makes it much easier to use and integrate into existing infrastructures. REST APIs are implemented by a wide variety of web services, web applications and cloud platforms, but can also be used to communicate with (industrial) devices.

OPC UA

OPC UA is an industrial communication standard for data exchange between automation devices and software systems.

With OPC UA, machines and devices from different manufacturers can provide data in a standardized format or receive data for control purposes. This requires an OPC UA server that “translates” between proprietary interfaces and the OPC UA standard.

On the other hand, software applications such as MES or ERP systems implement OPC UA clients to retrieve data or transmit it to controllers.

Main characteristics of OPC UA:

- Platform-independent and expandable

- Integrated security mechanisms (authentication & encryption)

- Complex information modeling

OPC UA has established itself as one of the most important standards in industrial automation across all industries. Due to features such as platform independence and technology abstraction, OPC UA is considered one of the most important technologies for digital transformation in industry.

When to use which technology? – Practical examples

Below we present some of the most common use cases for MQTT, REST and OPC UA.

1. Sensor-based real-time monitoring in production (MQTT)

A company in automotive manufacturing wants to record sensor data from machines in real time in order to detect anomalies at an early stage. MQTT offers an efficient solution with its publish-subscribe principle.

The sensors continuously send data to a central MQTT broker, which distributes it to the relevant systems. This ensures reliable and fast data transmission.

In addition to machine data, environmental parameters can also be monitored.

2. Cloud integration for industrial IoT applications (REST)

A manufacturer of sensors for industrial equipment needs an interface to transfer sensor data from a production hall to a central cloud platform.

REST APIs enable simple and standardized HTTP communication between the machines and the cloud.

The REST architecture offers the advantage that it can be easily integrated into existing MES and ERP systems and allows flexible scalability for analysis and optimization purposes.

3. Machine communication on a factory floor (OPC UA)

An manufacturing company wants to enable seamless communication between different control systems (PLC, SCADA) in a production hall.

OPC UA is ideal for this purpose as it not only transfers machine data in a standardized way, but can also map complex data models. The integrated security layer also ensures that communication is protected.

Conclusion – The right communication standard for your project

The choice of the right communication standard depends heavily on the specific requirements. While MQTT is ideal for IoT applications and low-resource systems, REST is ideal for web and cloud communication. OPC UA remains the first choice for industrial automation and machine communication.

The three communication standards are often combined – for example with OPC UA over MQTT, where OPC UA data is transmitted in the form of MQTT messages.

Which solution is the right one for your project?

Are you unsure which protocol is best suited to your application? Contact us – we will help you find the optimal solution for your production environment.

Production data management with manubes

Connect production systems to the manubes cloud and manage data and processes on a central platform. manubes uses edge technology and offers support for standard industrial interfaces such as MQTT, REST and OPC UA. Configure secure data transfers and make the most of your data.

Recent Comments