Explanation, Examples & Solutions

Machine Data Acquisition

Manufacturing companies use machine data in a variety of ways – from controlling and monitoring their systems to supporting investment decisions and predictive maintenance. This page provides a practical introduction to the topic of machine data acquisition.

Definition

What is machine data acquisition?

Machine data acquisition refers to the systematic collection of data on machine statuses and machine-related processes in industry.

The recorded data is forwarded to specialized software, databases or cloud platforms and made available for analysis and visualization.

The collection of plant data for control, monitoring and optimization purposes has been common practice in production for decades. Today, machine data acquisition forms the basis for the use of modern software systems – from supporting machine control and real-time process monitoring to predictive maintenance, digital twins and AI analyses.

Machine data acquisition is part of production data acquisition. Production data or operational data also includes data on orders, stock or personnel.

Machine Data

What is machine data?

Industrial machines and their control systems provide a wealth of information – from data on operating times to the quality of the products produced. Thanks to modern sensor technology, companies can record and monitor a large number of data points.

Relevant data that can be measured on a machine includes status data, process data, environmental data, product data and energy data. Below, we show some common examples for collected data.

Status / Operational data

- Current operating status (On/Off, Standby)

- Operating time

- Stops

- Failures

- Error messages

- Settings

- Maintenance data

Process data

- Speeds

- Feed rate

- Pressure in hydraulic systems

- Temperature measurements

- Vibration patterns

Environmental data

- Temperature

- Air humidity

- Air pressure

Product data

- Quantity

- Scrap rate

- Product properties (e.g. weight, thickness, consistency)

- Quality measurements (e.g. using image recognition systems)

Energy data

- Energy consumption per machine

- Energy consumption per item

- Energy efficiency indicators

Depending on the production environment, different data may be relevant. Companies in the food industry measure environmental parameters such as temperature and humidity to ensure compliance with hygiene regulations. In metal processing, data such as tool wear and spindle load are crucial.

Data sources

What are the sources of machine data?

Modern production facilities, control and measurement systems produce large amounts of data.

While a lot of data used to be recorded manually in the past, modern and automated machine data acquisition is based on the networking of sensors and machine controllers with suitable software systems.

Below we take a look at the most common sources of machine data.

Sensors

Sensors – integrated or external – are one of the main sources of machine data. Data from integrated sensors can often be recorded centrally via the programmable logic controller (PLC) of a machine. However, modern sensors can also communicate directly with machine data acquisition software.

Examples:

- Temperature sensors

- Pressure sensors

- Vibration sensors

- Position sensors

Programmable logic controllers (PLC)

A large part of machine data is recorded directly via the machine’s controller. A PLC provides data on the operating status, cycle times, quantities, process parameters such as temperature and many others.

The integration of machine controllers with software systems such as SCADA, MES and ERP is one of the most important steps in the implementation of machine data acquisition. While modern control systems often integrate standard interfaces such as OPC UA, older devices may require the conversion of proprietary protocols into suitable formats.

Retrofit solutions

In many production environments, older machines are still in use, often missing modern sensor technology and data interfaces. In order to use these machines as a data source for machine data acquisition, they can be retrofitted with external sensors. Data measured with these sensors could include vibrations, voltages or energy consumption, which provide information about the condition and performance of the machines.

Manual data collection

Even though today the majority of machine data acquisition is automated, the addition of manually recorded data can be valuable. Examples include the documentation of maintenance and quality checks or the transmission of special notes and observations by technical personnel. Data can be transmitted via connected terminals or mobile devices.

Practical example: Users of our manubes platform can scan QR codes or barcodes on materials using mobile devices to transmit data automatically. This makes it easy to implement solutions for material identification or similar use cases.

Why manufacturers collect machine data

Automated

machine control

Machine data such as temperature, pressure or speed are measured in real time and can be used directly to adjust control parameters, making the machine react automatically to changes. If deviations are detected, parameters such as feed speed or coolant supply can be adjusted accordingly.

Real-time

equipment monitoring

Suitable sensors monitor the condition of machines using relevant parameters such as temperatures or vibrations. Recording and visualizing this data in real time enables rapid responses to problems. In case of deviations from standard values, alarms can be triggered and manual or automated interventions can be carried out.

Data-driven

production planning

Daten wie Taktzeiten, Verfügbarkeit und Stillstände werden genutzt, um Aufträge optimal auf vorhandene Bearbeitungsstationen zu verteilen. Kurzfristig helfen Maschinendaten dabei, auf veränderte Kapazitäten zu reagieren, langfristig unterstützen sie eine bessere Nutzung der vorhandenen Anlagen. Auch bei der Planung von Neuanschaffungen benötigen Unternehmen eine gute Datenbasis.

Automated

machine control

Machine data such as temperature, pressure or speed are measured in real time and can be used directly to adjust control parameters, making the machine react automatically to changes. If deviations are detected, parameters such as feed speed or coolant supply can be adjusted accordingly.

Real-time

equipment monitoring

Suitable sensors monitor the condition of machines using relevant parameters such as temperatures or vibrations. Recording and visualizing this data in real time enables rapid responses to problems. In case of deviations from standard values, alarms can be triggered and manual or automated interventions can be carried out.

Data-driven

production planning

Daten wie Taktzeiten, Verfügbarkeit und Stillstände werden genutzt, um Aufträge optimal auf vorhandene Bearbeitungsstationen zu verteilen. Kurzfristig helfen Maschinendaten dabei, auf veränderte Kapazitäten zu reagieren, langfristig unterstützen sie eine bessere Nutzung der vorhandenen Anlagen. Auch bei der Planung von Neuanschaffungen benötigen Unternehmen eine gute Datenbasis.

Automated

machine control

Machine data such as temperature, pressure or speed are measured in real time and can be used directly to adjust control parameters, making the machine react automatically to changes. If deviations are detected, parameters such as feed speed or coolant supply can be adjusted accordingly.

Real-time

equipment monitoring

Suitable sensors monitor the condition of machines using relevant parameters such as temperatures or vibrations. Recording and visualizing this data in real time enables rapid responses to problems. In case of deviations from standard values, alarms can be triggered and manual or automated interventions can be carried out.

Data-driven

production planning

Daten wie Taktzeiten, Verfügbarkeit und Stillstände werden genutzt, um Aufträge optimal auf vorhandene Bearbeitungsstationen zu verteilen. Kurzfristig helfen Maschinendaten dabei, auf veränderte Kapazitäten zu reagieren, langfristig unterstützen sie eine bessere Nutzung der vorhandenen Anlagen. Auch bei der Planung von Neuanschaffungen benötigen Unternehmen eine gute Datenbasis.

Long-term

production optimization

Companies collect and analyze historical machine data in order to identify potential for improvement – e.g. excessive energy consumption, individual systems that limit output or frequent micro-stops that result in significant downtimes. In larger companies in particular, data from different sources and locations is often brought together in a central environment, structured within data models and evaluated in a targeted manner (including AI-supported analyses).

Predictive

Maintenance

Predictive maintenance is a modern maintenance concept based on machine data acquisition. By evaluating data such as wear and typical malfunction patterns, it is possible to predict when maintenance is necessary and schedule accordingly. The aim of predictive maintenance is not only to avoid breakdowns, but also to reduce the costs of unnecessary maintenances.

Quality control &

Traceability

Recording machine data helps to ensure product quality and, if necessary, makes it possible to fully trace where, when and under what conditions a particular product was manufactured. Relevant data can be linked to serial numbers, batch numbers or product IDs and documented for end customers, audits or to meet legal requirements.

Long-term

production optimization

Companies collect and analyze historical machine data in order to identify potential for improvement – e.g. excessive energy consumption, individual systems that limit output or frequent micro-stops that result in significant downtimes. In larger companies in particular, data from different sources and locations is often brought together in a central environment, structured within data models and evaluated in a targeted manner (including AI-supported analyses).

Predictive

Maintenance

Predictive maintenance is a modern maintenance concept based on machine data acquisition. By evaluating data such as wear and typical malfunction patterns, it is possible to predict when maintenance is necessary and schedule accordingly. The aim of predictive maintenance is not only to avoid breakdowns, but also to reduce the costs of unnecessary maintenances.

Quality control &

Traceability

Recording machine data helps to ensure product quality and, if necessary, makes it possible to fully trace where, when and under what conditions a particular product was manufactured. Relevant data can be linked to serial numbers, batch numbers or product IDs and documented for end customers, audits or to meet legal requirements.

Long-term

production optimization

Companies collect and analyze historical machine data in order to identify potential for improvement – e.g. excessive energy consumption, individual systems that limit output or frequent micro-stops that result in significant downtimes. In larger companies in particular, data from different sources and locations is often brought together in a central environment, structured within data models and evaluated in a targeted manner (including AI-supported analyses).

Predictive

Maintenance

Predictive maintenance is a modern maintenance concept based on machine data acquisition. By evaluating data such as wear and typical malfunction patterns, it is possible to predict when maintenance is necessary and schedule accordingly. The aim of predictive maintenance is not only to avoid breakdowns, but also to reduce the costs of unnecessary maintenances.

Quality control &

Traceability

Recording machine data helps to ensure product quality and, if necessary, makes it possible to fully trace where, when and under what conditions a particular product was manufactured. Relevant data can be linked to serial numbers, batch numbers or product IDs and documented for end customers, audits or to meet legal requirements.

Implementation

Implementation and procedure of machine data acquisition

Machine data acquisition includes both the integration of data sources and the transfer of selected data as well as their subsequent storage and further processing.

The most important steps in machine data acquisition are explained in more detail below.

Integration of data sources

Suitable interfaces and data protocols must be available in order to record data from sensors and controllers. Ideally, interfaces should be standardized across systems. With OPC UA, machine data can be provided in a standardized format regardless of the manufacturer. In other cases, REST APIs offer a way to selectively read device data. Missing interfaces may need to be implemented, e.g. by external OPC UA servers or middleware applications.

Configuration of data transfers

Software systems such as MES, ERP or cloud platforms serve as target systems for machine data. This requires configuring which data points are to be recorded, how often and under what conditions. If systems access data automatically such as through OPC UA clients or REST clients, corresponding configurations (endpoints, query intervals, etc.) can be made in the software.

Data storage

Captured machine data is stored within a target system. These can be simple databases, MES and ERP systems, central cloud platforms or data lakes and data warehouse systems. To enable analysis and further processing, the data must be transferred into a meaningful structure.

Data visualization and processing

Collected machine data is used in various ways. To enable (real-time) process monitoring and data-driven decisions, data can be visualized within suitable diagrams and dashboards, summarized into key figures or integrated into production reports. AI-supported analyses offer an opportunity to gain insights from large volumes of (unstructured) data.

Practical example: Machine data acquisition with manubes

With our manubes platform, manufacturers are able to connect machines via standardized interfaces and record data within custom data models. Data can be stored in a central location, visualized in real-time and processed through automated workflows.

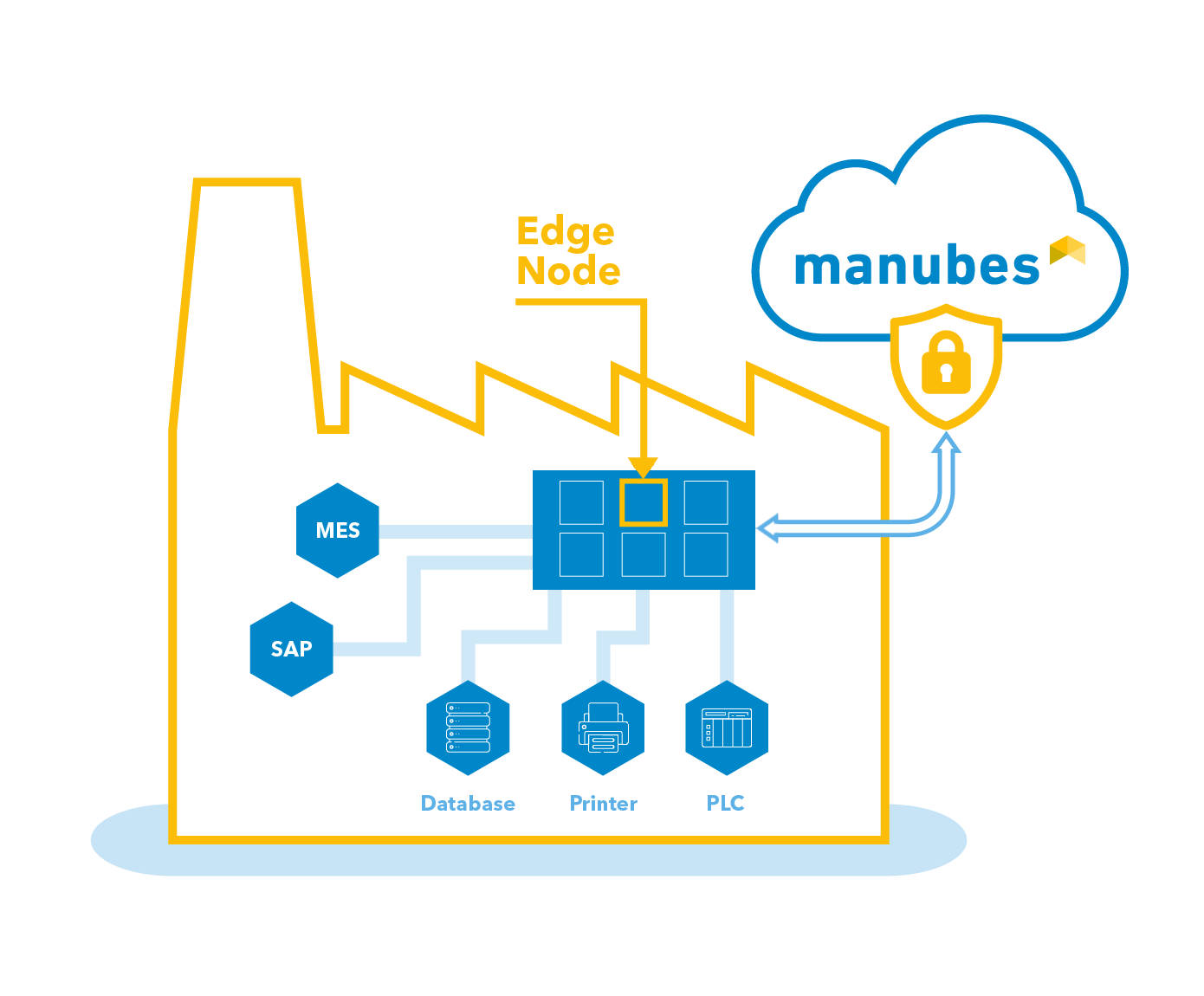

The connection to distributed sites and production systems is realized with Edge Nodes. These lightweight software components are installed on local computers or edge devices, enabling secure connections between machines, devices, local software systems and the manubes cloud environment.

manubes architecture: Connecting productions systems to the cloud

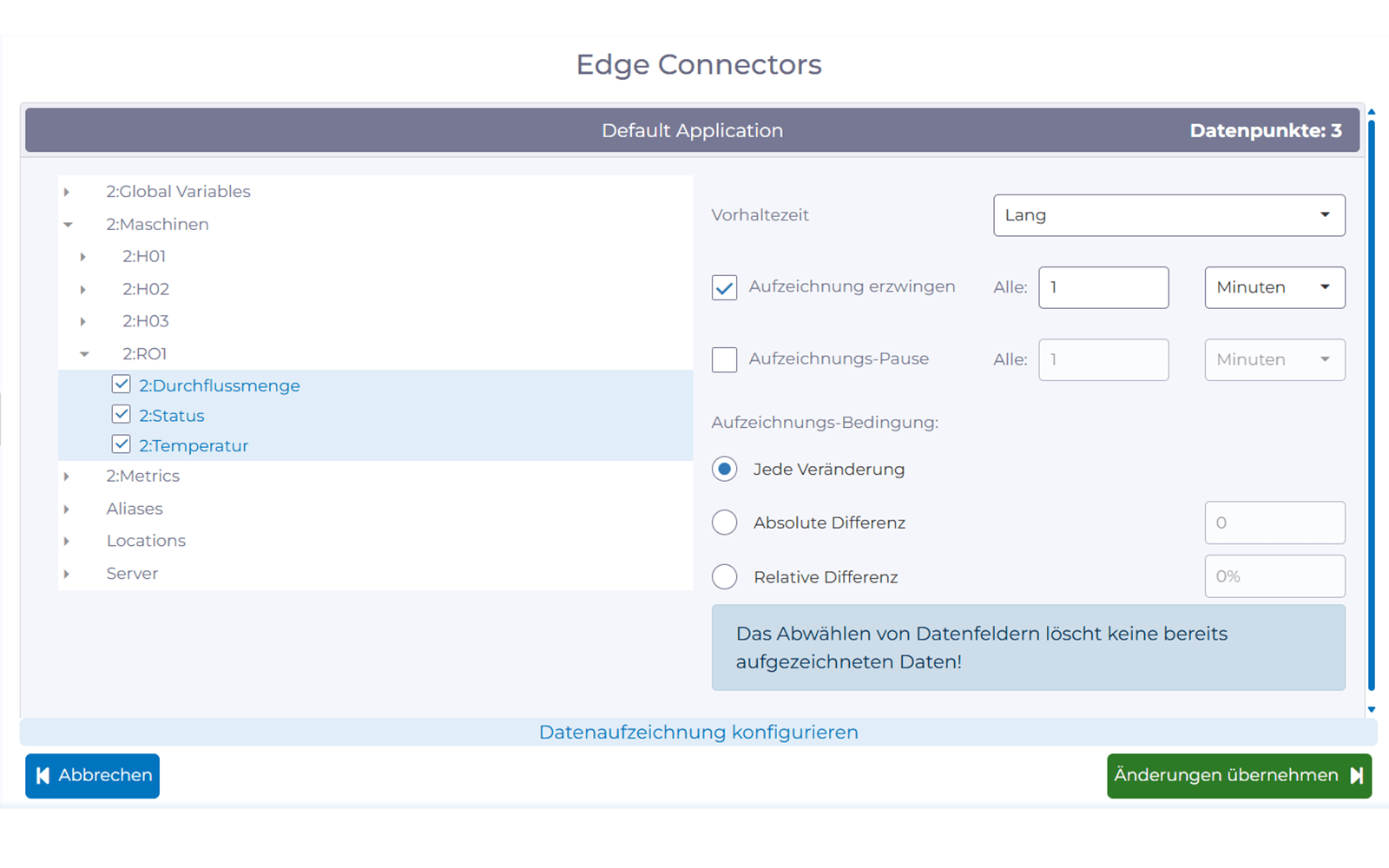

Edge Connectors are used to address specific systems and individually configure the data acquisition process. An OPC UA Connector makes it possible to read OPC UA data points in regular intervals. Other supported interfaces include MQTT, REST and SQL databases.

Configuration of OPC UA data acquisition

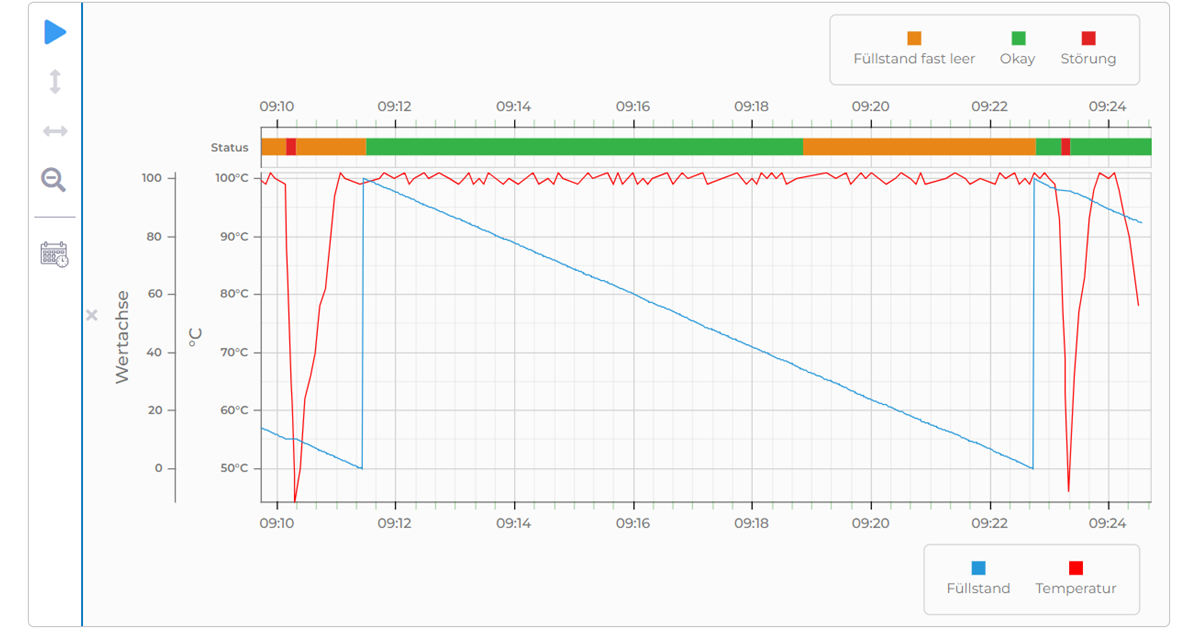

With the manubes Page Designer, users can create charts and link them to active data sources such as OPC UA servers. This makes it easy to visualize machine data in real-time.

Visualization of OPC UA real-time data

The manubes Datamodel Designer can be used to store machine data in a structured way, tailored to the processes and requirements of a specific company.

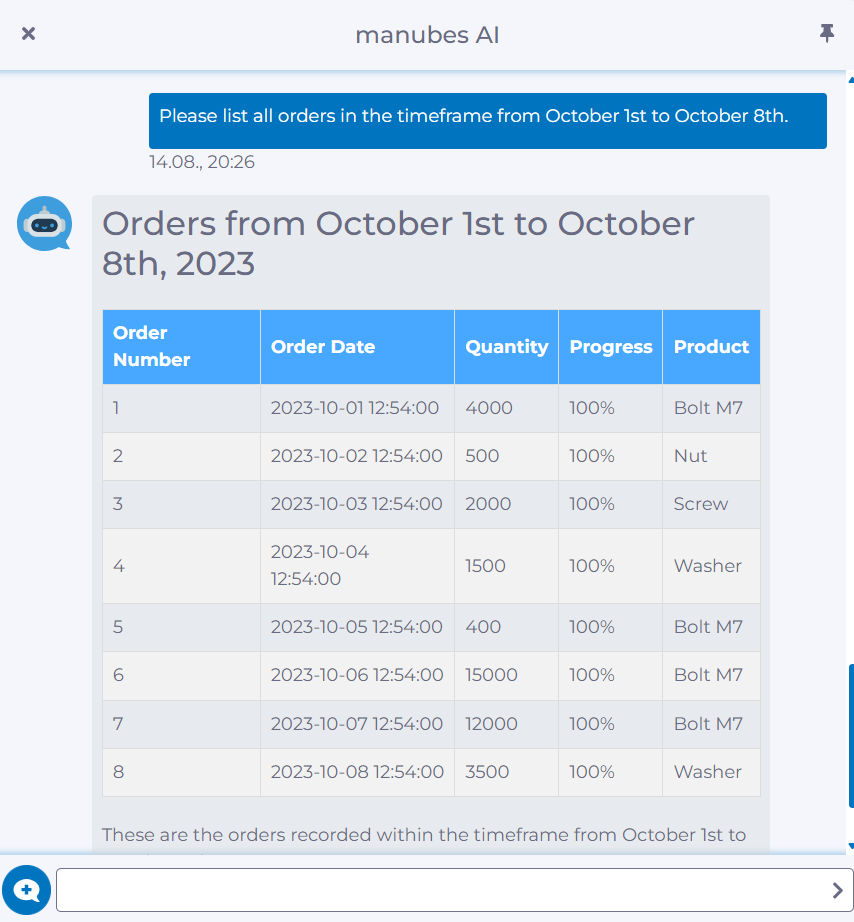

Once data has been stored, manubes users can utilize the Chat Assistant to analyze existing data models. The AI-powered helper provides information on historical developments, maintenances or current disruptions within seconds.

Integrated AI assistant

manubes is a specialized solution for companies in the manufacturing and process industry. The platform integrates a variety of tools and allows users to develop their own solutions in areas such as production planning, control and monitoring.

Discover manubes!

Cloud-based production management with manubes: Our innovative platform offers specialized tools for connecting production systems, managing and visualizing production data and automating production processes. manubes users benefit from a powerful infrastructure, worldwide access and maximum security.